Natural Dyes - Fibres

The Maiwa Guide to Natural Dyes

What they are and how to use them

About fibres, yarns, and cloth.

For the dyer, fibres are divided into two types: animal (protein) fibres such as wool, hair, and silk; and plant (cellulose) fibres such as cotton, linen, and hemp.

Mordant chemistry dictates the ease with which fibres may be dyed. Wools are the easiest. Silks are also dyed without much difficulty. Cotton presents a greater challenge, while even, level, consistent colour on linen is an accomplishment to be proud of.

Because the fibre types are fundamentally different, dye and mordant recipes are fibre specific. Generally speaking, protein fibres can be prepared to receive a dye through the addition of a mordant, while cellulose fibres require the addition of a mordant and a tannin. Mordants and tannins will be explained more fully in separate posts.

The world of natural dyes is one of relationships and complex molecules. It is almost impossible to make any statement that is absolutely true for all dyes, processes, or fibres. A beginner can gain satisfying results with the first attempt, but a lifelong learner who enjoys experimenting or investigation can find with natural dyes a limitless field of possibilities.

Dyeing can be done with fleece, yarns, cloth or garments.

Fleece dyeing is common for wools. The loose structure provides good access to the fibre and variations in shade will be evened out by the carding process. It is also possible to blend colours by combining two differently dyed fleeces into one yarn. Take care with heating wools. Too high a temperature or a sudden change in temperature will cause felting. Wool will benefit from a heated dyebath as the the scales in the fibre open slightly thus giving a better colour.

Yarns are the easiest to dye. It is best to tie them loosely into skeins. If you tie the skein too tightly the tie will create a resist and you will have made an ikat. Skeins can be lowered into the dyepot on a metal rod or loosely tied with another piece of yarn.

Woven materials are very satisfying to dye. The cloth surface provides an inviting field to play with resist and pattern techniques. Circulation in the bath is required to get even coverage and so larger pieces will require a suitably large dyepot . When dyeing consider both the tightness of the weave and the fibres in the weave.

Specialized equipment is sometimes used. A jigger is a machine consisting of rollers and a specialized dyebath designed to work with yardage. For Indonesian batik, dyeing without cracking the wax resist is considered a great accomplishment. For this reason the prepared batiks are hung on a rack which may be lowered into an extra-deep tank.

Garment dyeing can be an adventure. It is very satisfying to revamp old clothes through a dip in the dyebath. It is also possible to production-dye finished garments and again special machinery can be custom built or purchased. Garment dyeing is the trickiest method of dyeing. Watch out for synthetic stitching (it will not take on colour) and areas of wear (they will dye unevenly). For expensive or handmade garments testing is recommended. Even a garment that has been worn only a few times may take on perspiration from the owner. This can create noticeable (and perhaps embarrassing) areas of uneven dye coverage.

We use the term fiber to refer to anything being dyed: cloth, raw fibers or yarns.

What they are and how to use them

|

| Muga Silk |

About fibres, yarns, and cloth.

For the dyer, fibres are divided into two types: animal (protein) fibres such as wool, hair, and silk; and plant (cellulose) fibres such as cotton, linen, and hemp.

Mordant chemistry dictates the ease with which fibres may be dyed. Wools are the easiest. Silks are also dyed without much difficulty. Cotton presents a greater challenge, while even, level, consistent colour on linen is an accomplishment to be proud of.

Because the fibre types are fundamentally different, dye and mordant recipes are fibre specific. Generally speaking, protein fibres can be prepared to receive a dye through the addition of a mordant, while cellulose fibres require the addition of a mordant and a tannin. Mordants and tannins will be explained more fully in separate posts.

The world of natural dyes is one of relationships and complex molecules. It is almost impossible to make any statement that is absolutely true for all dyes, processes, or fibres. A beginner can gain satisfying results with the first attempt, but a lifelong learner who enjoys experimenting or investigation can find with natural dyes a limitless field of possibilities.

|

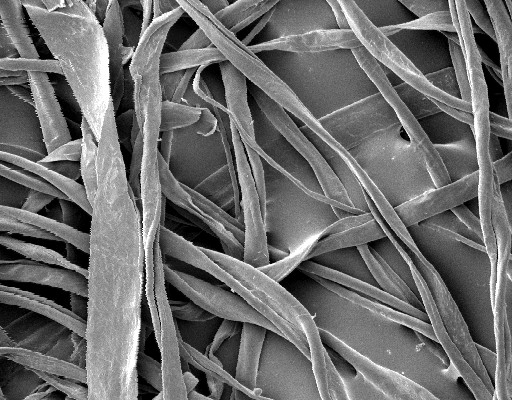

| Electron micrograph of cotton fibre. (Wikipedia) |

|

| Electron micrograph of wool showing scales. (US Agricultural Research Service) |

Dyeing can be done with fleece, yarns, cloth or garments.

Fleece dyeing is common for wools. The loose structure provides good access to the fibre and variations in shade will be evened out by the carding process. It is also possible to blend colours by combining two differently dyed fleeces into one yarn. Take care with heating wools. Too high a temperature or a sudden change in temperature will cause felting. Wool will benefit from a heated dyebath as the the scales in the fibre open slightly thus giving a better colour.

Yarns are the easiest to dye. It is best to tie them loosely into skeins. If you tie the skein too tightly the tie will create a resist and you will have made an ikat. Skeins can be lowered into the dyepot on a metal rod or loosely tied with another piece of yarn.

Woven materials are very satisfying to dye. The cloth surface provides an inviting field to play with resist and pattern techniques. Circulation in the bath is required to get even coverage and so larger pieces will require a suitably large dyepot . When dyeing consider both the tightness of the weave and the fibres in the weave.

Specialized equipment is sometimes used. A jigger is a machine consisting of rollers and a specialized dyebath designed to work with yardage. For Indonesian batik, dyeing without cracking the wax resist is considered a great accomplishment. For this reason the prepared batiks are hung on a rack which may be lowered into an extra-deep tank.

Garment dyeing can be an adventure. It is very satisfying to revamp old clothes through a dip in the dyebath. It is also possible to production-dye finished garments and again special machinery can be custom built or purchased. Garment dyeing is the trickiest method of dyeing. Watch out for synthetic stitching (it will not take on colour) and areas of wear (they will dye unevenly). For expensive or handmade garments testing is recommended. Even a garment that has been worn only a few times may take on perspiration from the owner. This can create noticeable (and perhaps embarrassing) areas of uneven dye coverage.

We use the term fiber to refer to anything being dyed: cloth, raw fibers or yarns.

1 comments

My yarn is made off 100 %wool and had a superwash treatment.

ReplyDeleteDoes the superwash treatment affect the dying results?

Thank you for your answer,

Corrie

We moderate comments to keep posts on-topic, avoid spam, and inappropriate language. Comments should appear within 24 hours.